Free Radical Process Design (FRPD) has developed a novel electrowinning technology (the Rotowinner™) that presents a groundbreaking advancement in electrowinning with its innovative scraped rotating electrode cell.

This cutting-edge technology offers exceptional mass transport rates and compact design, making it a game-changer in various applications.

The current design of the Rotowinner comprises a stationary anode, tailored to specific requirements, and a cylindrical cathode that rotates continuously.

What sets the Rotowinner TM apart from conventional electrowinning cells is its integration of innovative features, including direct scraping technology. This remarkable capability allows for uninterrupted harvesting of the product, streamlining the production process.

Moreover, the system incorporates a full reactor enclosure, prioritizing safety during operations and ensuring a secure environment for operators.

Anode and Cathode Configuration

The Rotowinner consists of a stationary anode and a rotating cylindrical cathode, both made of a specific material based on the application.

Electrolyte Bath

The electrodes are immersed in an electrolyte bath, typically containing a solution with metal ions that need to be extracted or plated onto the cathode.

Cathode Rotation and Turbulence

The cylindrical cathode rotates continuously, generating turbulence within the electrolyte bath, enhancing mass transfer, and facilitating efficient electrochemical reactions.

Explore how the RotowinnerTM System is revolutionizing various industries through our collection of compelling case studies.

Our groundbreaking technology is being developed for various applications including metal recovery, mine influenced water treatment, water softening, and green hydrogen production.

Free Radical Process Design (FRPD) embarked on the development of the Rotowinner to address the challenges encountered in the conventional copper electrowinning process. Consequently, FRPD successfully constructed the first containerized RotowinnerTM demonstration plant in 2022.

The core technology of electrowinning metals provides a wide scope for the RotowinnerTM to produce various metals.

The demonstration plant was operational at a South African base metal refinery (BMR) for 6 months. This plant was specifically designed to produce LME grade 2 copper from the BMR copper sulphate leachate feed and to purify process streams by removing undesired residual metals.

The RotowinnerTM technology demonstrated its potential to continuously produce final products while occupying a small footprint and requiring minimal operator intervention.

Through the Rotowinner TM technology, FRPD aims to revolutionize metal extraction and purification processes, offering enhanced efficiency, continuous production, and improved product quality, ultimately driving advancements in sustainable metal production.

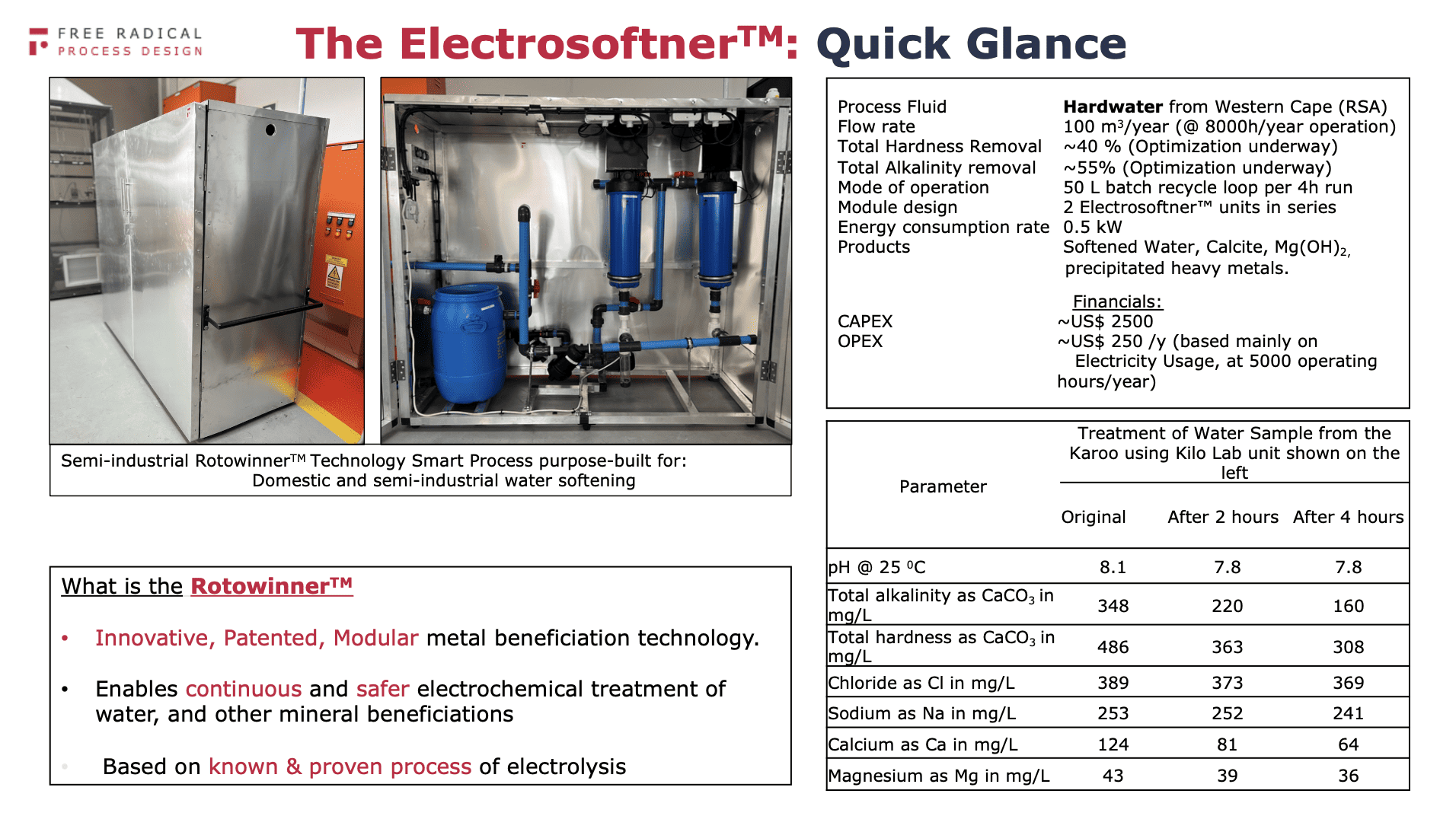

FRPD introduces the ElectrosoftnerTM, a cutting-edge salt-free water softener that effectively addresses temporary and permanent water hardness. Built upon the innovative RotowinnerTM technology, this modular unit operates in both continuous and batch-recycle modes, delivering softened water, hydrogen, and calcite/milk of magnesia mixture.

The ElectrosoftnerTM boasts economic advantages, including low energy requirements and zero waste generation. Its compact packaging ensures easy transport and handling, while the design allows for scalability, accommodating larger volumes of hard water for treatment. Experience efficient and sustainable water softening with the ElectrosoftnerTM from FRPD.

The RotowinnerTM Demonstration plant was deployed for purifying underground mine-water in the Northern Cape Province, South Africa.

The RotowinnerTM underwent continuous electrolysis of mine influenced brine water supplied from a Reverse Osmosis (RO) plant.

Both the harvested solid and treated water products from the RotowinnerTM Plant were thoroughly analyzed.

The solid product primarily consisted of hardness-causing species, with calcium (34%) and magnesium (64%) being the main components, alongside manganese (1%).

The RotowinnerTM system treated a feed stream at a flow rate of 2.2 m3/h for approximately 8 hours, effectively processing approximately 16 m3 of water.

The results indicated that the RotowinnerTM is highly capable of treating mine influenced brine solution and effectively softening hard water without the need for additional chemicals.

At FRPD, we firmly believe in the importance of sustainability. The Rotowinner TM project aligns with our commitment to promoting a circular economy and reducing the reliance on traditional methods of mine influenced treatment, which often contribute to further environmental degradation.

By implementing the RotowinnerTM technology in mine influenced Water treatment, we aim to minimize the environmental footprint, optimize resource utilization, and foster a greener future.

At FRPD, we are dedicated to pioneering advancements in precious metal recovery. Our ongoing development efforts focus on utilizing the groundbreaking RotowinnerTM technology to extract precious metals from high and low concentration streams, while promoting sustainable recycling practices.

The RotowinnerTM technology, currently in development, holds immense potential for transforming the recovery process of precious metals from streams with low and high concentrations. By harnessing the unique capabilities of the RotowinnerTM system, we aim to maximize recovery yields and minimize resource waste.

As part of our commitment to sustainability, the RotowinnerTM technology aligns with our mission to promote recycling and reduce dependence on primary resource extraction.

By recovering precious metals from low concentration streams, we contribute to the circular economy and minimize the environmental impact associated with traditional mining practices.

Through our ongoing development efforts, we strive to unlock the full potential of the RotowinnerTM technology for precious metal recovery from low and high concentration streams.

By harnessing this innovative solution, we aim to provide industries with a more sustainable, efficient, and economically viable method for recycling precious metals.

Stay connected with FRPD to stay updated on our progress as we continue to advance the RotowinnerTM technology in

Precious metal recovery

Mine influenced water treatment

Hydrogen Production

Contact us today to learn more about our project and how we can work together to make a positive impact on our planet.